Macerator 6620

| HP recommended | 80 to 120 HP |

| Pickup width | 66" | 165 cm |

| Operating speed | 5 to 10 mph | 8 to 16 km/h |

| Swaths cuts | Up to 14' | 426 cm |

| Weight | 3800 lbs | 1633 kg |

Macerator 6620

| HP recommended | 80 to 120 HP |

| Pickup width | 66" | 165 cm |

| Operating speed | 5 to 10 mph | 8 to 16 km/h |

| Swaths cuts | Up to 14' | 426 cm |

| Weight | 3800 lbs | 1633 kg |

- Options

- Other products recommended

- Complementary informations

- Complete specifications

- Photos/videos

Options

Other products recommended

Complementary informations

COMPARE

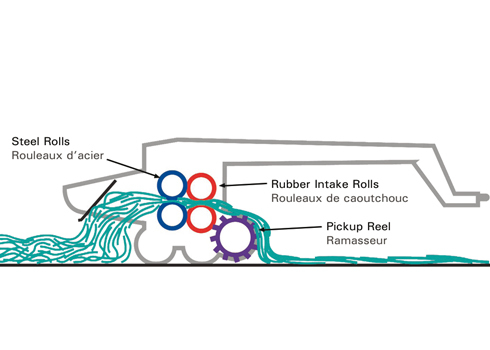

HOW IT WORKS

More thorough than a conditioner

The Agland Macerator features a double set of rolls, allowing it to do a more thorough job than any other system on the market. The pickup reel feeds the crop to the rubber intake rolls where the swath is flattened out before it is fed through the steel patterned rolls. The air pressure system helps maintain an even pressure on the rolls without crushing the hay.

Faster drying

Maceration takes place between the steel rolls. The top steel roll runs at a slightly different speed than the bottom roll. This action cracks and nicks the stems of the plants and removes some of the wax, resulting in cell rupture. This allows the moisture to escape at a quicker rate than with conventional equipment, promoting a much faster dry down.

Preserves nutrients and color

Long exposure during dry down causes leaching of nutrients and color. Less exposure to damaging sun rays helps preserve both nutrients and color. This makes the finished product a lot more valuable for export and domestic use.

More palatable

Maceration helps to soften the hay, preserves the protein content and exposes more plant sugar to allow more efficient silage fermentation, making all of the hay more palatable and increasing the digestibility of the hay or forage, which may translate* into:

- increased energy

- significant weight gains

- increased milk production

*Depending on condition and type of animal. For more detailed information on the benefits of maceration contact us for a summary of the Prairie Agricultural Machinery Institute (PAMI) test results.

INDEPENDANT STUDY REPORTS

A considerable amount of research has gone into the benifits of macerated hay. The following are a few excerpts of various reports.

"Laboratory tests showed a drying rate for macerated material was roughly double that of conditioned material. This fact, coupled with the wider and shallower windrow or mat formed by the Macerator, accounted for a field drying rate of about 4-6 times faster than with a mower conditioner."

"The alfalfa dehy industry found a 43% saving in gas usage for dehydrating crop which had been macerated compared to a conditioned crop."

Source - University of Saskatchewan, Dept. of agricultural and biosource engineering

"A recent feeding experiment with dairy cows in early lactation showed that maceration increased alfalfa dry matter intake and milk production. This increase in hay consumption resulted in a significant increase of milk per day. Milk fat remained the same and protein content was significantly higher."

Source - Savoie and Block

"Researchers have found that the main advantages of forage maceration over conventional mowing conditions are : faster field drying, less fiels losses when there is no rain, improved digestibility of the fibre and more efficient silage fermentation."

Source - Special PAMI report

"Macerated alfalfa dries faster. The reduced drying time could help avoid rain damage, minimize yield losses from traffic damage and permit more timely irrigation."

Source - Source - Dan Putnam, University of California, Davis extension forage specialist

"Maceration increased in vitro digestibility of alfalfa stems by as much as 39%."

Source - Sirohi et al

Copies of complete rapports are available on demand.

Complete specifications

| HP recommended | 80 to 120 HP |

| Overall width | 10'6" | 315 cm |

| Overall length | 11'4" | 345 cm |

| Overall height at work | 3'6" | 105 cm |

| Overall height for transportation | 5'6" | 165 cm |

| Pickup width | 66" | 165 cm |

| Tires | 11L-15 SL |

| Operating speed | 5 to 10 mph | 8 to 16 km/h |

| Swaths cuts | Up to 14' | 426 cm |

| Swaths width | 5'6" | 168 cm |

| PTO | 540 or 1000 RPM |

| Weight | 3800 lbs | 1633 kg |

Design and specifications subject to change without notice.